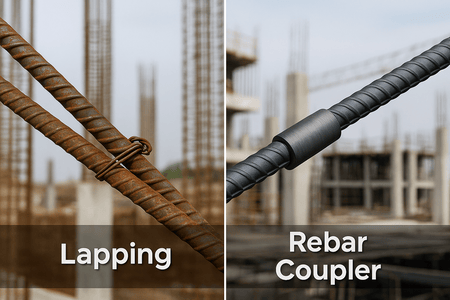

The construction business demands more strength and accuracy than ever in the world today. Engineers and constructors are always on the lookout of new materials and ways that will make things safer and efficient simultaneously. Rebars are connected with the help of Rebar couplers in concrete structures. In the past, rebars were joined by lapping, which means that steel bars had to overlap, which used more material. Rebar couplers do away with this necessity by providing a direct, end-to-end mechanical connection that works better under stress. Construction is becoming cleaner, quicker, and more dependable thanks to cooperation from rebar coupler manufacturers in India.

What Are Rebar Couplers

A rebar coupler connects two reinforcing bars. By screwing or clamping the ends of rebars together, it makes a continuous load route. The couplers are more dependable than lapping due to being able to transfer stress to one bar to another without depending on the concrete surrounding them to be strong. Scintilla, rebar coupler manufacturers ensure that the tools are easy to operate, durable, and suitable to be applied in constructing homes, to large scale infrastructural projects.

Benefits of Using Rebar Couplers in Construction

The main advantages that are changing how construction is done today are as follows:

Superior Structural Integrity

Rebar couplers let bars transfer 100% of their force to each other. This implies that the stress doesn’t only stay in the concrete, like it does during lapping; instead, it goes straight through the steel. This makes the structural parts stronger and longer-lasting.

Material Savings

You don’t need to overlap rebars when you use couplers. This cuts down on the quantity of steel needed by a lot, which helps builders save money and materials. It also makes planning for rebar easier and cuts down on waste on the job site.

Space Optimization

Rebar couplers reduce crowding in reinforced areas by preventing overlaps. This helps make the plan clearer, especially in tight or severely reinforced areas like columns, joints, and foundations.

Flexibility in Design

Couplers provide you more choice when designing structures. They can link rebars at different angles and let you make bars of different lengths. This is quite helpful for complicated buildings like bridges and tunnels.

Comparison of Rebar Couplers and Lapping

Here is a list of the main ways why rebar couplers are better than standard lapping:

Load Path Continuity

Scintilla, Best rebar coupler in India makes sure that the load route stays open, which means that performance stays the same. Lapping, on the other hand, depends a lot on how well the concrete is placed to transfer stress.

Load Transfer

Lapping depends on how well the concrete bonds, but couplers transfer load directly by mechanical methods. This makes behavior more predictable, especially when there are dynamic or seismic forces at work.

Structural Integrity

Couplers make the connection more stable and safer. When pouring, lapped bars might move, which weakens joints. Couplers keep everything in line, which makes everything more stable.

Conclusion

The way current construction is done is changing, thanks to rebar couplers. They make things stronger, cut down on steel waste, and make reinforcement work more accurate and efficient. As buildings get higher and more complicated, they require more reliable rebar connections. Due to their dependability and performance, mechanical couplers are fast taking the place of lapping, which used to be the standard approach. Scintilla couplers are a good choice for builders who want to increase quality while keeping prices down. This change is forging a stronger future, one link at a time, from Scintilla as a rebar coupler manufacturers in India.