India’s building industry is changing quickly, with a strong push toward new ideas, lower costs, and safer structures. The switch from old-fashioned lap splicing to newer rebar coupler is one of the many changes that have led to this growth. Rebar coupler manufacturers in India are now very important for providing high-quality, dependable rebar coupling solutions that can fight on a global scale. For engineers and builders, the question isn’t whether to use couplers or not. That’s why rebar couplers made in India are a better choice than standard splicing.

Understanding the Basics: Lap Splicing vs. Rebar Coupling

In traditional lap splicing, two support bars are stacked on top of each other and bound together with wire. This has been the standard for decades, but if it’s not done right, it can weaken the structure, use more steel, and make joints more crowded.

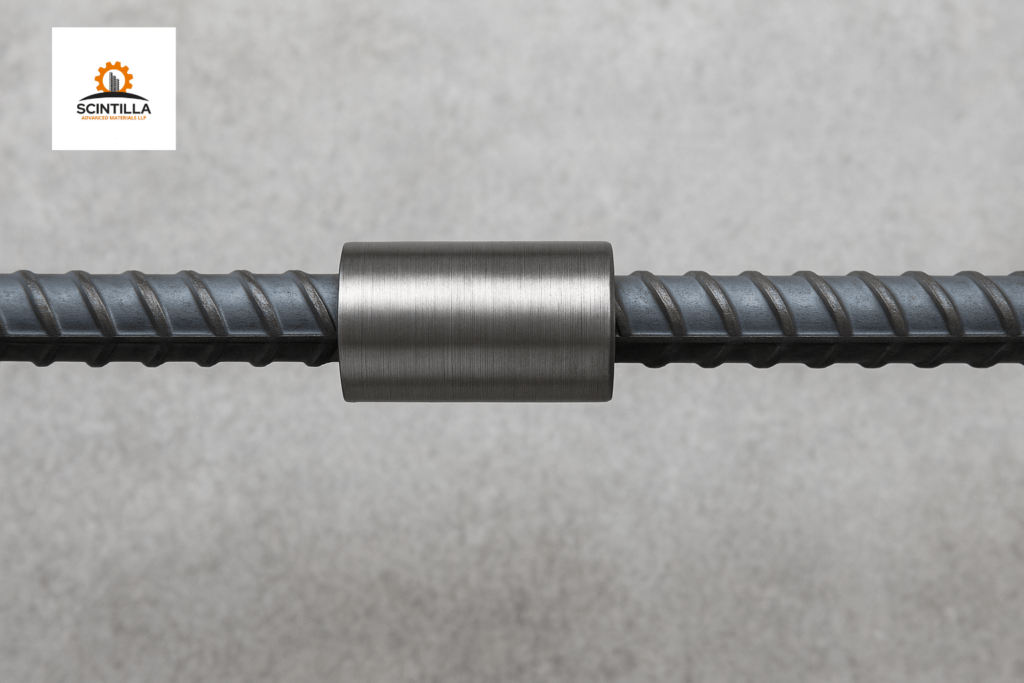

Rebar coupler, on the other hand, are motorized parts that connect two rebars end-to-end without them touching. These devices make sure that axial loads are transferred directly and that the support stays connected. They are a good option for lap joints because they work well, are consistent, and meet building codes when they come from reputable Rebar coupler manufacturers in India.

Material Savings and Cost Efficiency

Rebar coupler save steel, which is fantastic. Traditional lap splicing requires stacking bars 40 to 60 times their width, which wastes material, especially on infrastructure and high-rise projects.

Indian companies are now making precision-engineered couplers that get rid of this problem completely. Steel reduction decreases material costs and makes the building lighter, saving much more on concrete and construction.

Enhanced Structural Integrity

In building, structural strength is essential. A lot of what makes lap splices work is the pressure between the bars that are overlapping and the concrete around them. This can cause problems, especially when there are a lot of loads or earthquakes. Rebar coupler, on the other hand, connect bars directly and mechanically, making the load path more stable.

Couplers made in India are made to meet both Indian and foreign standards for their tensile strength, shear resistance, and ability to handle wear and tear. A lot of Rebar coupler manufacturers in India also sell goods that have been checked out and approved by outside labs. This makes sure that essential parts of the structure are very reliable.

Space Optimization and Improved Site Workability

When you do lap splicing, it’s common for strengthening zones to get crowded. This is especially true where columns and beams meet or where earthquakes happen. For this reason, it is hard to pour concrete properly, which can cause poor compaction, holes, or honeycombing.

With rebar couplers, there is a lot less crowding. They make it easier to place and vibrate concrete because they simplify the layout of the rebar. This improves the quality of the end structure. Rebar coupler manufacturers in india have many styles, including threaded, sleeved, and swaged, to meet the needs of different sites and make installation easier.

Conclusion

Indian-made rebar couplers are a better, more cost-effective, and more technically sound option to traditional lap splicing. They not only cut down on waste and improve the standard of construction, but they also speed up the process and make the structure stronger. Switching to rebar couplers made in India is a smart move that fits with the future of modern buildings for projects that need to be safe, efficient, and last a long time. We have strict quality control measures in place to make sure that our rebar couplers build buildings that are safer and last longer. This is why Scintilla is a trusted name in the construction industry.