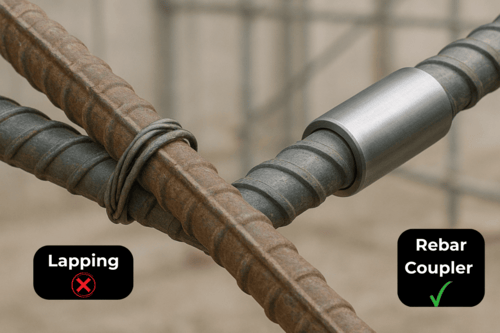

Mechanical rebar couplers, sometimes called mechanical splices, are quickly taking the place of traditional lap joints in modern construction. Couplers provide a direct steel-to-steel connection, which results in far more reliable and constant performance than lap splicing, which relies on the bond between the concrete to transmit load. Couplers are becoming a more dependable and effective option in a wide range of construction applications by eliminating lap length computations, decreasing reinforcement congestion, and maintaining structural integrity. Let’s talk about why rebar couplers are becoming a better alternative than traditional overlapped joints in current construction.

Benefits of Rebar Couplers

Rebar couplers are a better way to deal with many of the problems that come up with typical lapped joints. They make all kinds of construction projects more efficient, safer, and flexible in terms of design.

Avoid Rebar Congestion

Space is particularly important in the design of reinforced concrete. When you use traditional lap splicing, a lot of rebars end up overlapping in one point, which makes the region crowded. Not only does this heavy bundling make it difficult to pour concrete, it can also damage the relationship between the different parts of the structure. Couplers fix this problem by connecting two bars directly without overlapping. This makes the reinforcement arrangement more open and easier to work with. It’s a cleaner, safer option that helps keep the structure strong during and after construction.

Maximize Floor Space

Smart people in high-end high-rise buildings know how to make the most of the room they have as towns get smaller. By cutting down on the amount of strengthening needed at the splice points, rebar couplers make concrete sections smaller. This implies that the walls and columns are thinner, which gives you more floor space. More room on each floor not only makes the design better, but it also makes the house worth a lot more money.

Reliable Load Transfer

Overlapped joints rely a lot on the concrete around them to transfer loads between bars. The joint’s strength might get worse if the concrete breaks or diminishes over time. Rebar couplers make a direct connection between two pieces of steel, which makes it easier to move loads.

Protect Formwork During Construction

When steel bars are overlapped and stretched, they might get in the way of putting up formwork. Workers might have to bend or move the formwork around bars that stick out, which might cause damage or misalignment. Couplers fix this problem by keeping starting bars flat with the surface until they are needed. This lowers the strain on the formwork and makes installation easier. It’s a tiny thing that can save you money on repairs and time.

Save Material and Cost

Lap splicing may use a lot of material, especially if the overlaps need to be longer. This means that there will be more steel and greater expenses. Couplers let you cut and connect bars with very little waste. Not only does this conserve raw resources, but it also cuts down on the expenses of moving and processing them. Couplers are a more economical choice because of the cumulative savings on steel and labor over time.

Support Sustainable Design

When people care about the environment, using less steel means leaving behind less carbon, which is becoming more and more important. Couplers help green buildings by cutting down on waste and encouraging better resource use. Their use is in line with green certifications and sustainability objectives, making them perfect for eco-friendly construction projects that want to lessen their effect without losing quality.

Conclusion

Rebar couplers aren’t merely a contemporary replacement for lap joints; they change the game for the construction industry. Their benefits go well beyond the surface, including cleaner designs, lower costs, safer structures, and longer-lasting buildings. Couplers provide the strength and accuracy that modern construction needs as structures grow higher and spaces get smaller. Get the best range of reinforcement rebar coupler supplies from India. Discover more now!